Watch Making

Swissmaster experts at their best

Swissmaster’s experts make some of the best and perfect replica Rolex available online, All the process of making is done by hand. From the watch movement to assembling all the watch, our experts do it with the help of magnifying machines for precision and perfection.

A perfect replica Rolex depicts the efforts and expertise of those who crafted it. Like our name Swissmaster, we are masters in making the perfect Swiss Replica Rolex which is going to accompany you a lifetime. Our Swiss watchmakers put all their effort in crafting a single piece and it goes under several technical processes to be a perfect cloned Rolex. Not everyone can afford it and a few people have our Cloned Rolex due to Prices of perfections and time involved, You are fortunate to have us.

PVD Coating with Gold or Platinum

Rather than using old-fashioned coating methods like Electro-chemical plating, we use PVD that creates a thick layer of 18CT Gold on Gold models and platinum on respective models. PVD is the process when gold or platinum is evaporated in special equipment and then it is deposited on the watch along with Titanium Nitride. The entire process of PVD plating is conducted under supervision of experts watchmakers and with the latest equipment to make our watches flawless,

Perfect hands of Swissmaster cloned Rolex

Pre-rhodium plating, Rhodium Plating, Degreasing, Leaching, and many others, these are all names of the processes we conduct at our Swiss labs to craft perfect Cloned Rolex hands. At the front end, brass hands are the core of a watch that should depict how prestigious you and your watch are. Meeting the Rolex standards is not a jack-of-all-trades job; it requires extensive expertise and skill, and we are masters in it.

Swissmaster’s perfect Dials

Our Experts at Swissmaster do the dials in a professional way with top-notch machinery available for the process. We excel in the market with our expertise in crafting the best dials for our Swiss replica Rolex. From a brass plate to finishing, making drills, and creating raised parts, we lacquer or electroplate our dials to the perfection.

Respectively, metal dials are crafted from Silver or Gold, and they undergoes several processes untill the finishing. Different techniques and processes that include drilling, printing the markings, and PVD coating are carried out.

The most visible part of a Replica Rolex is its Symbol crafted on the dial. We do the symbol and hour markings with the help of nozzle pens and the luminescent substance Super-Luminova

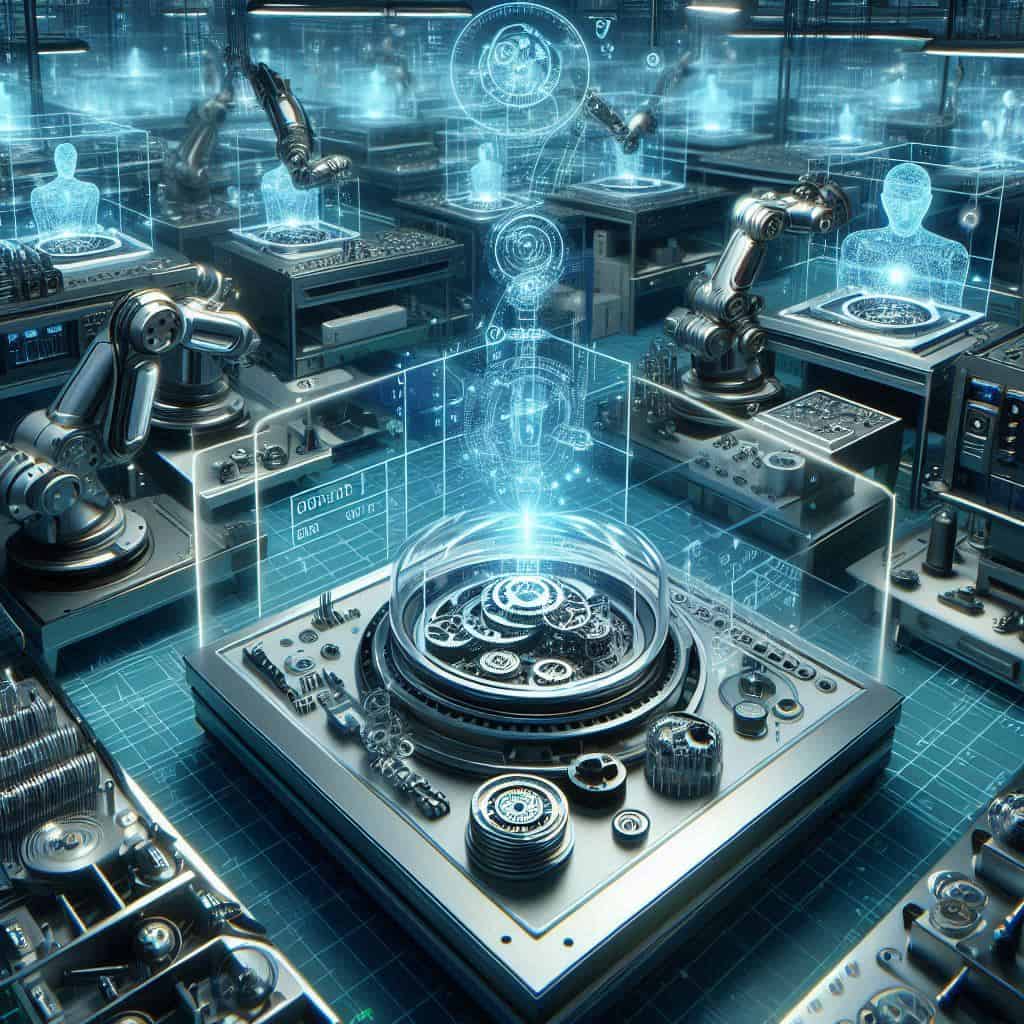

Technology and Expertise at Swissmaster Labs

Wearing a Rolex is a joyful sensation, ever you know what is involved behind the scenes in crafting a cloned Rolex? It requires the latest technology and experts to craft a masterpiece. Different parts of a watch require a different sets of machines and technology to pass before becoming a proud Swissmaster replica Rolex. We make use of high-speed cameras, electron microscopes that can magnify up to 40,000 times, and different chemical tests commencing devices.

We use the latest technology not only for testing purposes, but also crafting the movement and dials, and bracelets, of which all require extensive machines and processes to undergo. We make use of electron microscopy for movements, equipment for chemical analysis and list goes on.

Each part requires extensive testing for different environments. Like movements are tested for the time decay, dials are tested for ultra-violet rays, crystal to impact, and bracelets for extensive movement and grip.

Perfect Atmosphere and Environment

A perfect cloned Rolex is made with dedicated equipment with extensive experience, and under a controlled environment. Our production lab maintains a specific atmosphere for every process. Humidity and temperature in each area of the production unit should be maintained according to the devices and we monitor it with the latest equipment. Imagine your Replica Rolex showing condenses of traces while going in low temperatures area, it happened if a Cloned Rolex is cased up in a high temperature atmosphere. We do know what is the right atmosphere for each process and we do maintain it.

Assembling Precision

Each part of our Swissmaster Rolex is assembled carefully with the help of the latest technology. To start with, Swiss cloned movement is attached with the Dial. A machine with video screen is then used to attach the hands to axels of the movement, with the Swiss precision it is going to run for a lifetime. At the end, our Swiss cloned Rolex is tested in a controlled environment by our watchmaker to make it certain that everything is correct.

State of the art movement Lab

At our Watch Lab in Geneva, the movement of our watch undergoes several processes before becoming part of a Replica Rolex. There are many processes that involve manual and automated workarounds, and all the tasks are managed by a robust software program. This software guides the handlers and intercepts the chain to do the specific job on the movement. It is not like less than any other state of the art assembly unit of other respective industries.

To undergo the COSC test, our movements are wound by machines daily for consecutive 15 days. Machines monitor the seconds hand and follow elimination criteria that consist of almost 70 tests. This rigorous testing allows our movements to be a part of Replica Rolex by Swissmaster.nu.

More Tests and Final Product

Before a Replica watch leaves our lab, it undergoes numerous tests that ensure that our customers can enjoy it a lifetime, From waterproofing test to shape, color, rotation, power reserve, automatic winding, any many more, our watchmaker assembles or opens it several time. A pressure of 300 bars is applied to the watch by latest machines to ensure the waterproofness of our watches. Dials, straps, and bracelets are thoroughly verified before casing up the entire watch.